FR-4 to kod klasy materiału trudnopalnego, oznaczający materiał kompozytowy na bazie żywicy epoksydowej i tkaniny z włókna szklanego, który jest szeroko stosowany w produkcji płytek PCB i izolacji elektronicznej.

FR-4 to kluczowy materiał szeroko stosowany w przemyśle elektronicznym. Jego podstawowe cechy i zastosowania to:

1. Definicja i istota

• Gatunek materiału, a nie konkretna nazwa: FR-4 to kod klasy ognioodporności ustalony przez NEMA (National Electrical Manufacturers Association) oznaczający, że żywica jest żywicą epoksydową, materiał wzmacniający to tkanina z włókna szklanego, a klasa ognioodporności spełnia normę UL94 V-0.

• Skład: Składa się głównie z czterofunkcyjnej żywicy epoksydowej, wypełniacza oraz tkaniny z włókna szklanego klasy elektronicznej. Wytwarzany jest w procesie laminowania w wysokiej temperaturze i pod wysokim ciśnieniem.

2. Najważniejsze cechy

• Ognioodporność: Spełnia normę UL94 V-0, a podczas spalania ulega samoczynnemu gaszeniu.

• Parametry elektryczne: stabilna stała dielektryczna (Dk) (np. 4,5), doskonała izolacja, nadaje się do obwodów o wysokiej częstotliwości.

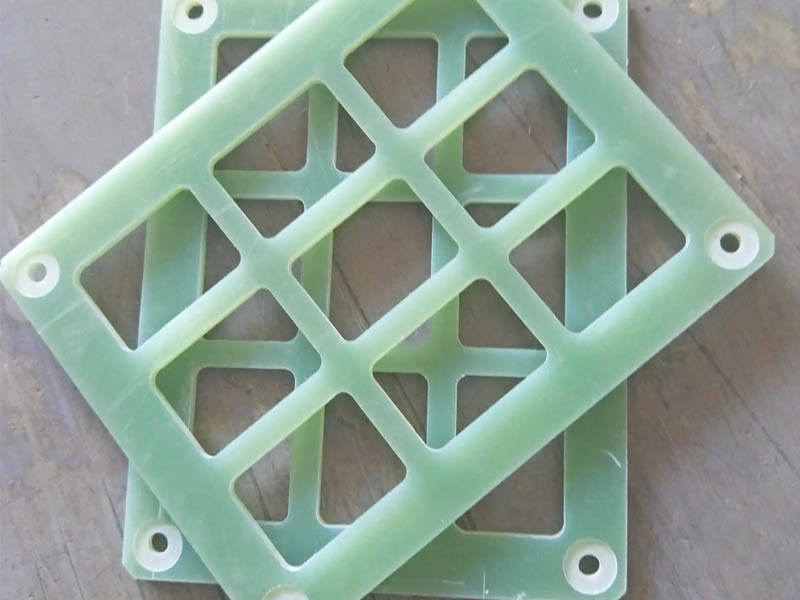

• Wytrzymałość mechaniczna: Wysoka sztywność, odporność na ciepło i wilgoć, możliwość precyzyjnej obróbki.

• Zarządzanie temperaturą: Niski współczynnik rozszerzalności cieplnej (CTE), odpowiedni do środowisk o wysokiej temperaturze.

3. Obszary zastosowań

• Produkcja płytek PCB: Jako główny materiał podłoża, jest stosowany w płytkach obwodowych wielowarstwowych (takich jak płytki sterowników LED czterowarstwowe) w celu zapewnienia kompatybilności elektromagnetycznej i obciążalności prądowej.

• Elementy izolacyjne: w tym płyty izolacyjne transformatorów, części izolacyjne silników, płyty wzmacniające FPC itp.

• Urządzenia przemysłowe: takie jak koła zębate do szlifowania, stoły testowe itp., które wymagają dużej wytrzymałości mechanicznej.